Why choose us

Consultancy

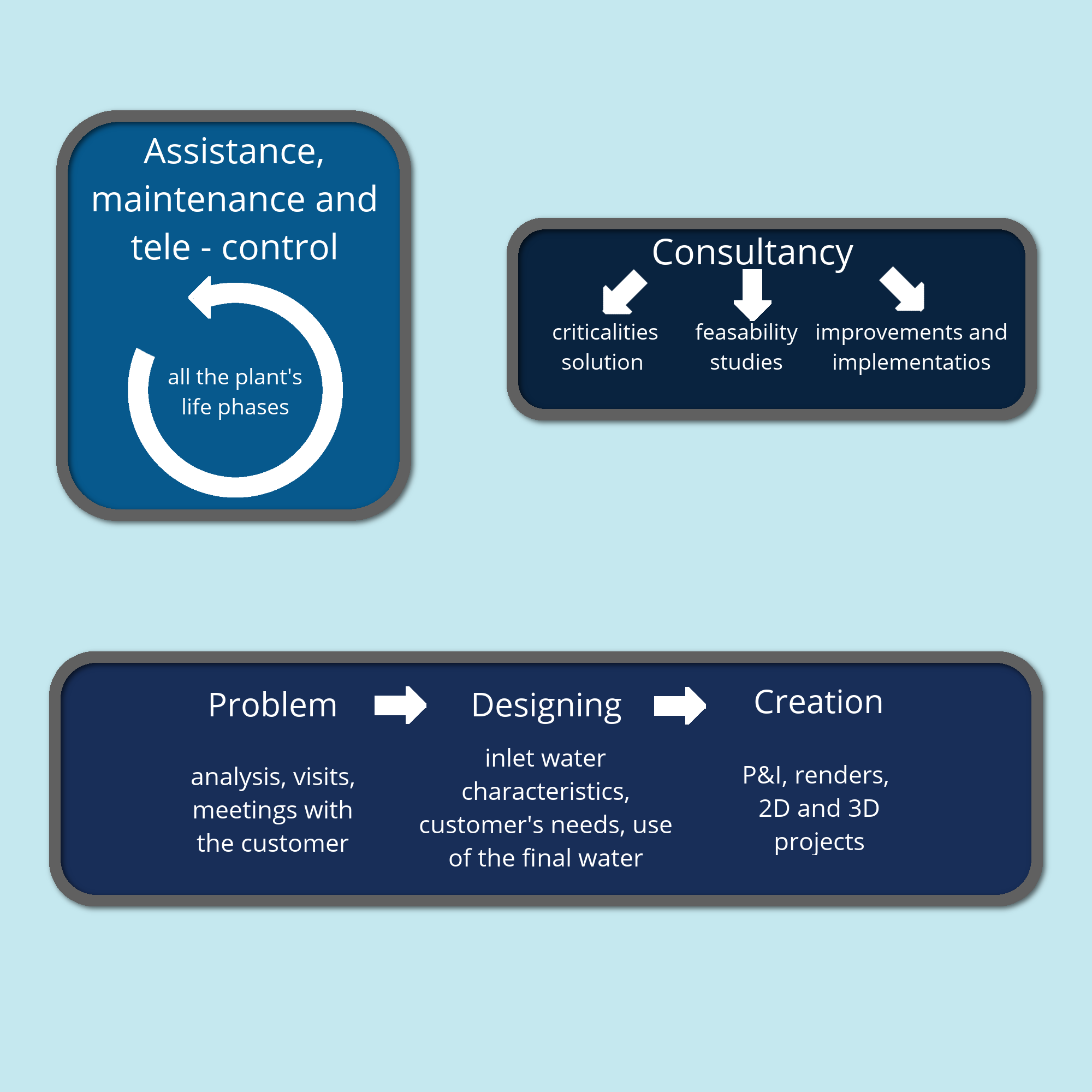

PPM offers to its customers consultancy services, to evaluate the problems, conducting specific feasibility studies finalized to the evaluation of systems to increase water quality in compliance with industry regulations. Thanks to our experience we are able to propose different solutions to solve every problems regarding water treatment, helping the customers to evaluate the best option from the point of view of the quality – price ratio and of the eco sustainability. PPM conducts consultancy services also in existing plants which present some critical issues. Our expert staff is able to provide indications on which components must be replaced or implemented to increase the efficiency of the plant, decreasing the management costs. Every evaluations is conducted by expert and professional staff, through the visits, analysis and samples execution .

Designing

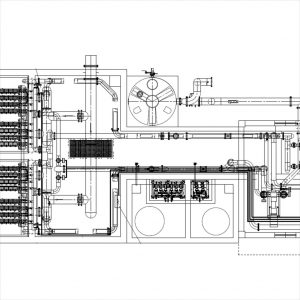

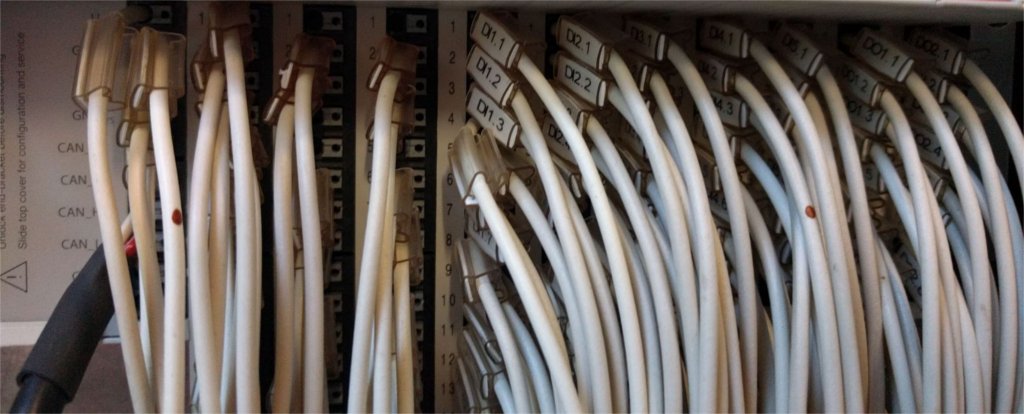

PPM boasts a long-time experience and a considerable know – how in water treatment plants' designing from every points of view: hydraulic, electric and programming. o design an efficient plant, optimizing the quality – price ratio and in compliance with the technical industry regulations, to know and to study some preparatory data is necessary. IThe preparatory data are collected and evaluated by our expert staff, by way of the preliminary relationship with the customer, possible visits and samples. The necessary data are the chemical and physical evaluation of the inlet waters, the customer's needs, the final use of the treated water and consequently the chemical and physical characteristics that it must have after the treatment. All those elements are evaluated and studied to elaborate a designing solution that satisfies all the technical requirements, using the most high quality materials and the best available techniques, without burdening on the customer economically. Once the designing direction is established in the preliminary phase, we can pass to real designing phase, in which our staff composes “on paper” what will be realized. A schematic representation of the functional relationships between all the components of the system, the control points and the different automations, i.e. a P & I (Piping and Instrumentation) diagram, is created. The plant's real structure is elaborated, in terms of kind of instrumentation and its position, valves and components, paths between the different instrumentations, control devices position and for each line the kind of pipe to use is individuated. The plant structure is represented in 2D and in 3D with the most advanced softwares, among which AutoCAD, Solid Works, creating the real renders to give to the customers a concrete idea of the development of the plant in the space. In the design phase the electric schemes of the plant, the supply of the different components, the realisation of the electric panels and all the control and regulation elements are studied. In the design phase also the management aspect is involved, on the basis of the technical characteristics of the system and on the customer's needs. A significant aspect of the design is represented by the PLCs, programming, which will be the management centre of the plant in the different work phases of the plant and they will signal any problems. Also in this aspect PPM takes advantages of the best available softwares, as SIMATEC and SCADA. During the designing plant'stechnical specifications are written, in those documents all the components of the plant, their technical characteristics and how the products must be assembled are described.

Plants' assistance, maintenance, management and tele – control

PPM offers to its customers every type of services also after the plant's implementation or in functioning plants, in every phase of their life. We provide a maintenance plant service, that allows to have the best work reliability, identifying and avoiding in advance problems and damages. In this way all the functioning parameters of the plant are monitored and the problems are promptly solved.

An assistance service is constantly available, in the case of damages or problems of every kinds. The assistance can concern every aspects of the plant: hydraulic, electric or programming. We are able to provide a prompt and efficient service, ensuring as much as possible the to the customer.

Our plants can be equipped with PLCs which guarantee a tele – control system, that can be visualized both from us and the costumers. It allows to control constantly all the work parameters of the plant, as the flow rate, the treated volumes, the chemical products consumption, the pH and the redox potential of the final water. The tele – control allows us to verify at distance if a plant signals problems and which interventions must be done. It also permits us to evaluate if to go physically to the plant is necessary or if it's possible to solve the problem from our offices, in order to do not burden unnecessary costs on the customer. In the case in which to go physically to the plant is necessary , the tele – control allows us to be more efficient, permitting us to prepare the necessary materials and the instrumentations in advance, without loss of time.

Customized contracts

PPM offers to its customers different kinds of customized contracts, depending on the customer's needs and the technical characteristics of the plant, as for example:

- maintenance service, including a defined number of interventions on the plant, with a frequency to plan with the customer;

- plant management service, in which our qualified staff provides completely to all the maintenance, as the check of the work parameters and the supply of the chemical components;

- Assistance / maintenance service with the tele – control by us and also by the customer, including a defined number of interventions;

- Every others kinds or combination of interventions, to plan with the customer.